Biomass Gasification Power Plant

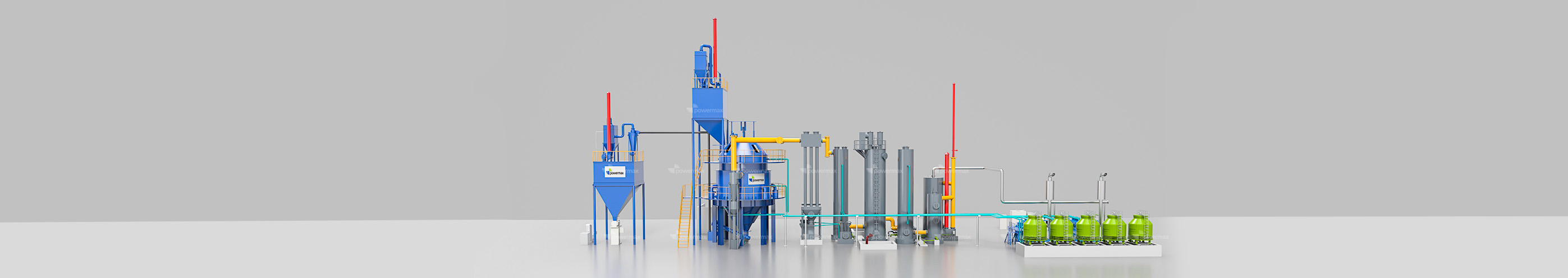

POWERMAX BIOMASS GASIFICATION POWER PLANT

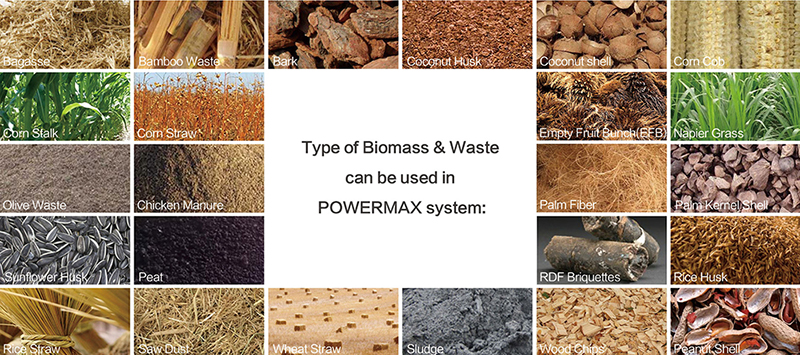

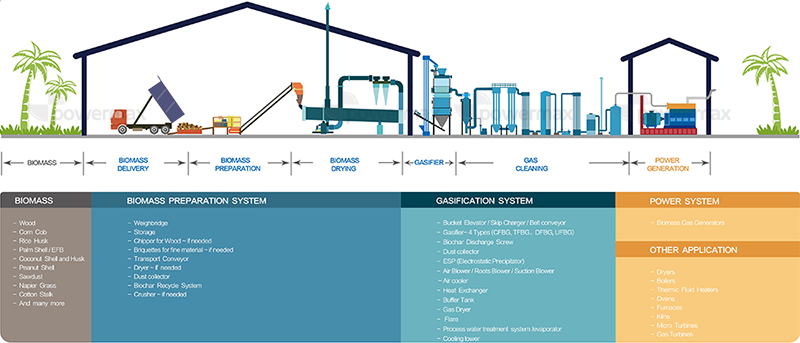

The basic principle of POWERMAX’s biomass gasification system(abbreviated as BGPS) is to convert Agriculture and forestry products and wood processing remains(including rice husk, wood powder,branches, offcuts, corn straws, rice straws, wheat straws, cotton straws, fruit shells, coconut shells, palm shells, bagasse, corn cobs and etc.) into combustible gas.

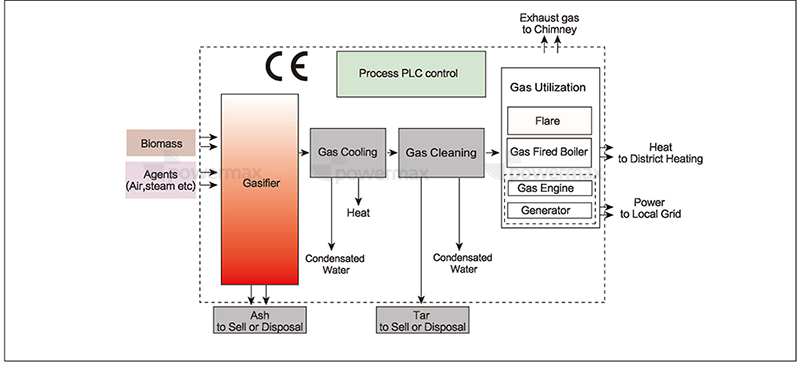

Our biomass gasification process includes three steps. The First step is biomass gasification, which convert biomass into syngas.The Second step is syngas purification.The producer gas coming from gasifier usually contains contaminants including dust, coke, tar and etc. The contaminants will be removed by the purification system to ensure normal operation of gas engine.

The Third step is power generating in gas engine. The high temperature exhaust gas may be reused by waste heat boiler to generate steam or hot water for civil or industrial use.Steam turbine may also be considered to make a gas-steam combined cycle power plant, which will increase the total efficiency.

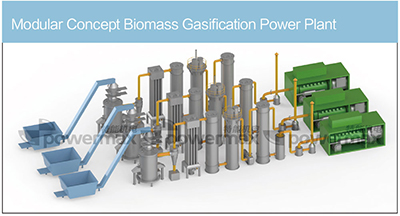

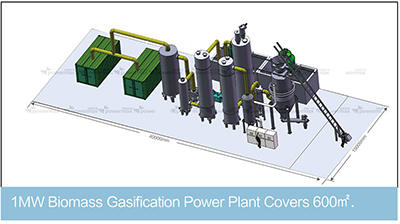

The POWERMAX biomass gasification power generation systems are based on a modular concept and are able to applicable for 50-20000KW biomass power station.

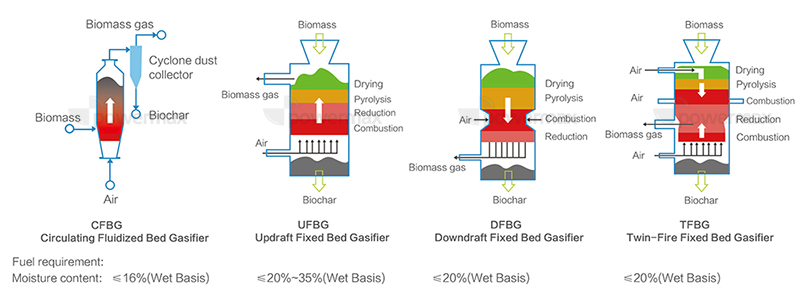

There are four series of biomass gasification systems offered by POWERMAX which range from 50-2000KW of power generation:

CFBG(Circulating Fluidized Bed Gasifier) Series,

UFBG(Updraft Fixed Bed Gasifier) Series,

DFBG(Downdraft Fixed Bed Gasifier) Series,

TFBG(Twin-fire Fixed Bed Gasifier) Series.

CFBG(Circulating Fluidized Bed Gasifier) Series,

UFBG(Updraft Fixed Bed Gasifier) Series,

DFBG(Downdraft Fixed Bed Gasifier) Series,

TFBG(Twin-fire Fixed Bed Gasifier) Series.

A series biomass generator sets from 50KW to 1200KW are developed by POWERMAX to combine with POWERMAX advanced gasification technology.

These gas generator sets are using the high efficiency Siemens technology alternators,Chinese top brand medium speed gas engine(500-1500rmp) with advanced European engine control systems. The high performance of the POWERMAX biomass gasification plants and the later production of electricity with the gensets represents a competitive solution when compared with conventional boiler-fired system.

These gas generator sets are using the high efficiency Siemens technology alternators,Chinese top brand medium speed gas engine(500-1500rmp) with advanced European engine control systems. The high performance of the POWERMAX biomass gasification plants and the later production of electricity with the gensets represents a competitive solution when compared with conventional boiler-fired system.

Comparing with other renewable power generating system,POWERMAX-BGPS is characteristic of:

1) Flexibility. Gas engine,gas turbine and even waste heat

recovery boiler may be used considering various power plantcapacity requirements. It ensures high power generating

efficiency. Different capacities of biomass power generation

plant can be designed with various types of POWERMAX-BGPS system.

2) Clean technology. Biomass, as one kind of renewable energy,

may reduce the emission of carbon dioxide causingfrom fossil fuel.Nitrogen oxides emission is very limited in our biomass gasification power generating system because of low temperature(700℃-1200℃)。

3) Economical. POWERMAX-BGPS is capacity flexible.Even small size biomass power plant is also profitable process and less land requirements make biomass gasification power plant more economical comparing with other renewable energy.Generally speaking,biomass gasification power generating is the most economical technology in renewable power generating is the most economical technology in renewable power generating plant,the cost of which is nearly the same as small-size conventional power plant.

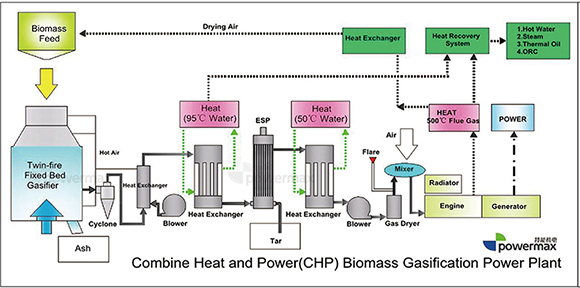

ABOUT CHP

Combined heat and power(CHP) also known as cogeneration,is an efficient, clean, and reliable approach to generate power and thermal energy from a single fuel source.By installing a CHP system designed to meet the thermal and electrical base loads of facility, CHP can greatly increase the facility’s operational efficiency and decrease energy costs. At the same time, CHP reduces the emission of greenhouse gases, which contribute to global climate change.

POWERMAX provides four types biomass gasifiers for different fuels and applications

BIOMASS GASIFICATION POWER GENERATION SYSTEM GENERAL FLOW CHART

What is Biomass Gasification?

Gasification is: Thermo - chemical conversion of Biomass to combustible fuel gas called Biomass Gas.

Biomass is: Carbon bearing plant matter such as wood chips, rice husk, corn cob …

Four Stage Conversion Process: Biomass is converted to Biomass Gas in a‘Gasifier’in four stages : drying, pyrolysis, oxidation and reduction.

Biomass Gas conversion of: Carbon Monoxide (CO), Hydrogen (H2), Methane (CH4) Carbon Dioxide (CO2) and Nitrogen (N2).

Biomass Gas is used as: Fuel Gas to substitute or replace any fossil fuel in thermal application.

Gasification is: Thermo - chemical conversion of Biomass to combustible fuel gas called Biomass Gas.

Biomass is: Carbon bearing plant matter such as wood chips, rice husk, corn cob …

Four Stage Conversion Process: Biomass is converted to Biomass Gas in a‘Gasifier’in four stages : drying, pyrolysis, oxidation and reduction.

Biomass Gas conversion of: Carbon Monoxide (CO), Hydrogen (H2), Methane (CH4) Carbon Dioxide (CO2) and Nitrogen (N2).

Biomass Gas is used as: Fuel Gas to substitute or replace any fossil fuel in thermal application.

Fuel Gas in Gas Genset to produce electricity.

Biochar: When added to soil, biochar has great capacity to retain nutrients reducing fertilizer requirements while increasing crop growth, health and yields. Research is confirming benefits of adding biochar to soil such as: Moderating soil acidity; Increased water retention ability of soil;Increased in number of beneficial soil microbes;Increase number of nitrogen fixing microbes in soil. Biochar can improve almost any soil. Areas with low rainfall or nutrient-poor soils will benefit the most.Biochar can reverse soil degradation and create sustainable food and fuel production in areas with nutrient depleted soils, scant organic resources, and insufficient water and chemical fertilizer supplier. Biochar acts to accommodate beneficial microbial activity in soils. Mixed to soil at a ratio of 0.4kg/m2 biochar has been shown by various studies to significantly improve soil conditions and enhance crop growth.

Feedback form contact with us