Powermax 300 Series Coal Gas Generator Set: High-Efficiency Industrial Solutions

Why Choose Powermax 300 Series?

The Powermax 300 Series Coal Gas Generator Sets are engineered for maximum return on investment in industrial waste-to-energy applications. Key advantages include:

- Direct Grid Connection: Outputs at 10.5kV, 6.3kV, or 400V eliminate the need for costly step-up transformers, reducing initial capital expenditure.

- Unmatched Durability: A low-speed (500-600r/min), large-bore design drastically reduces wear, extending service life and minimizing maintenance costs.

- High Overall Efficiency: Combined Heat and Power (CHP) capability utilizes exhaust heat, boosting total system thermal efficiency to over 70%.

- Fuel Flexibility & Safety: Designed to safely utilize a wide range of low-pressure industrial gases (syngas, BFG, COG, etc.) with a multi-tier safety system.

- Intelligent Operation: Integrated monitoring enables remote management, automatic control, and predictive maintenance for reliable, unattended operation.

1. Introduction and Project Scope

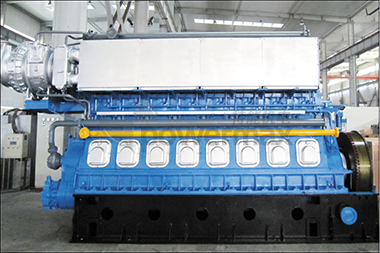

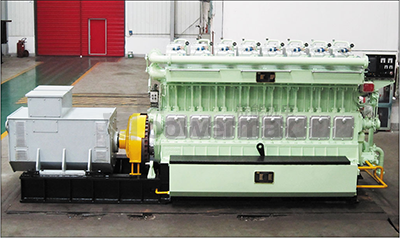

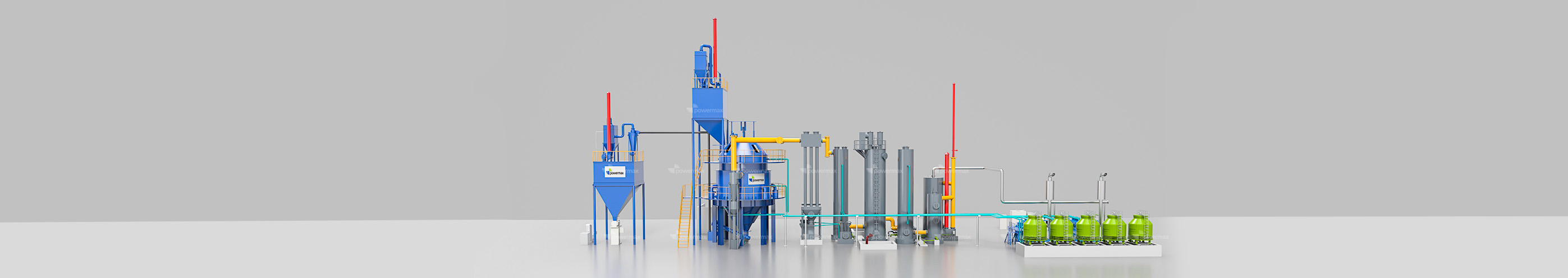

The Powermax 300 series coal gas generator sets represent a pinnacle of engineering in the field of clean energy power generation and the comprehensive utilization of industrial waste heat. In the modern industrial landscape, where energy efficiency is paramount, our coal gas engine and generator sets provide a reliable bridge to sustainability. These units are expertly designed to process a wide variety of combustible gases, including but not limited to syngas (synthetic gas), straw gas, coal gas, natural gas, biogas, blast furnace gas, coke oven gas, and blue carbon gas.

The core design philosophy of the 300 series focuses on low-speed stability, with rated speeds optimized at 500r/min and 600r/min. Our power range is extensive, spanning from 400kW up to 3000kW, catering to both medium-scale facilities and large-scale industrial power plants. Each coal gas generator is a product of rigorous research and development, ensuring that it can convert various raw combustible materials into high-quality electrical energy with minimal downtime.

2. Engineering Heritage and R&D Evolution

The foundation of our coal gas engine technology is the heavy-duty Xichai 300 diesel engine. By leveraging the inherent mechanical advantages of a large cylinder bore and a long stroke, our engineers have successfully adapted this platform for gaseous fuels. We have integrated advanced gas engine and genset technology from leading global manufacturers while conducting localized improvements to handle the unique chemical compositions of different industrial gases.

Our targeted R&D efforts have been specifically focused on the combustion characteristics of coal gas. This ensures that the engine's reliability and combustion efficiency are not compromised, even when the gas quality fluctuates. Consequently, the Powermax generator sets can maintain smooth operation and run for longer periods under full load conditions. Furthermore, the interconnection of these sets is designed for maximum convenience, allowing for seamless integration into existing grids or local micro-grids.

3. Fuel Gas Specifications and Requirements

To ensure the peak performance of your coal gas engine and gensets, the fuel gas must undergo a pre-treatment process. The gas should be properly purified, filtered, and subjected to gas-liquid separation to ensure it is stabilized before it reaches the combustion chamber.

Crucial Fuel Gas Intake Specifications:

- Temperature Management: If the source gas is generated at a high temperature, it must pass through a dedicated cooling system. The gas temperature must not exceed 40 °C prior to entering the engine.

- Pressure Stability: Required pressure ranges between 2.5kPa and 10kPa, with a pressure change rate of ≤1kPa/min.

-

Purity Standards:

- Tar content: ≤50mg/Nm³

- Impurity particle size: ≤5μm

- Total impurity content: ≤30mg/Nm³

- Hydrogen Sulfide (H2S): ≤50mg/Nm³ (recommended)

- Ammonia (NH3): ≤20mg/Nm³

- Moisture Control: Moisture content must be maintained at ≤40mg/Nm³ to prevent internal corrosion.

- Energy Density: The required gas calorific value must be ≥4MJ/Nm³ to sustain efficient power output.

300 Series 600-1400kW Coal Gas Generating Set Technical Specification (50Hz/60Hz)

| Item | Technical Specification | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Generator Sets | Model of the Set | 600GFLS | 700GFLS | 1200GFLS | 1400GFLS | ||||

| Rated Power (kW) | 600 | 700 | 1200 | 1400 | |||||

| Rated Voltage (kV) | 0.4 | 0.44 | 0.4 | 0.44 | 0.4 | 0.44 | 0.4 | 0.44 | |

| Rated Current (A) | 1083 | 984 | 1263 | 1148 | 2165 | 1968 | 2526 | 2296 | |

| Rated Frequency (Hz) | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | |

| Power Factor (COS Φ) | 0.8 Lagging | ||||||||

| Excitation Mode | Brushless | ||||||||

| Phase & Connection | 3 Phase 4 Wire | ||||||||

| Generator Model | 1FC6 SIEMENS | ||||||||

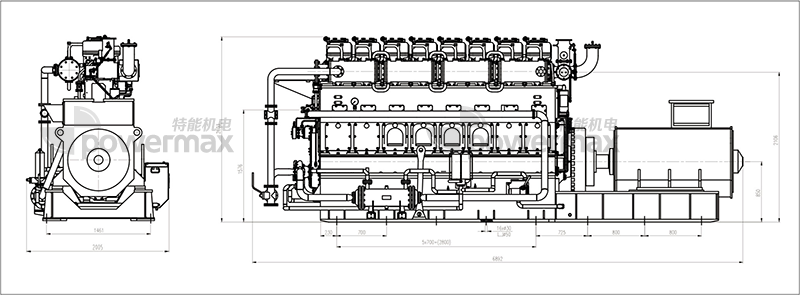

| Overall Dimensions (mm) | 6500*1830*3100 | 8287*2421*2782 | |||||||

| Net Weight (kg) | 22000 | 40000 | |||||||

| Engine | Model of Engine | TNJD-8300Q3 | TNJD-8300Q4 | TNJD-16V300Q3 | TNJD-16V300Q4 | ||||

| Type | Water-cooling, Four-stroke, Spark plug ignition, Open combustion chamber, Naturally aspirated | ||||||||

| Cylinder Arrangement | In-line 8 cylinders | V-type 16 cylinders | |||||||

| Cylinder Diameter (mm) | 300 | ||||||||

| Stroke (mm) | 380 | ||||||||

| Rated Power (kW) | 660 | 770 | 1320 | 1540 | |||||

| Speed (r/min) | 500 | 514 | 600 | 500 | 514 | 600 | |||

| Rotation Direction | Counterclockwise | ||||||||

| Start-up Mode | Compressed Air | ||||||||

| Exhaust Temp (°C) | ≤580 | ||||||||

| Gas Intake Temperature (°C) | ≤40 | ||||||||

| Gas Pressure (kPa) | ≥2.5 | ||||||||

| Oil Consumption (g/kWh) | ≤1.0 | ||||||||

4. 300 Series High-Power Pressurized Coal Gas Gensets (800-3000kW)

Designed for large-scale industrial applications, the pressurized (supercharged) 300 Series offers superior power density and efficiency. By utilizing advanced supercharging and inter-cooling technology, these coal gas generator sets deliver outputs ranging from 800kW to 3000kW, making them the ideal choice for heavy-duty power plants and substantial energy recovery projects.

Technical Specifications: 800-3000kW Coal Gas Generating Sets

| Item | Technical Specification | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Generator Sets | Model | 800GFLS | 900GFLS | 1000GFLS | 1200GFLS | 1500GFLS | 1700GFLS | 1800GFLS | 2000GFLS | 2400GFLS | 3000GFLS | ||||||||||

| Rated Power (kW) | 800 | 900 | 1000 | 1200 | 1500 | 1700 | 1800 | 2000 | 2400 | 3000 | |||||||||||

| Rated Voltage (kV) | 0.4 | 0.44 | 0.4 | 0.44 | 0.4 | 0.44 | 0.4 | 0.44 | 0.4 | 0.44 | 0.4 | 0.44 | 0.4 | 0.44 | 0.4 | 0.44 | 0.4 | 0.44 | 0.4 | 0.44 | |

| Rated Current (A) | 1443 | 1312 | 1624 | 1476 | 1804 | 1640 | 2165 | 1968 | 2706 | 2460 | 3067 | 2788 | 3248 | 2952 | 3609 | 3280 | 4330 | 3936 | 5413 | 4920 | |

| Rated Frequency (Hz) | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | |

| Power Factor | 0.8 Lagging | ||||||||||||||||||||

| Excitation | Brushless | ||||||||||||||||||||

| Phase & Connection | 3 Phase 4 Wire | ||||||||||||||||||||

| Generator Model | 1FC6 SIEMENS | ||||||||||||||||||||

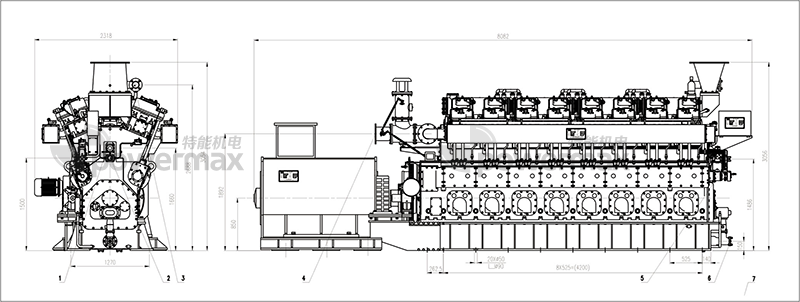

| Dimensions (mm) | 6500*1830*3100 | 7264*2300*3465 | 8904*2360*3286 | 8287*2421*2782 | 10410*2760*3420 | ||||||||||||||||

| Net Weight (kg) | 23000 | 30000 | 40000 | 40000 | 60000 | ||||||||||||||||

| Engine | Model | TNJD-8300T | TNJD-G6300T | TNJD-G8300T | TNJD-16v300T | TNJD-G16v300T | |||||||||||||||

| Type | Water-cooling, Four-stroke, Spark plug ignition, Open combustion chamber, Supercharged, Inter-cooled | ||||||||||||||||||||

| Cyl. Arrangement | L-8 | L-6 | L-8 | V-16 | V-16 | ||||||||||||||||

| Diameter (mm) | 300 | ||||||||||||||||||||

| Stroke (mm) | 380 | ||||||||||||||||||||

| Rated Power (kW) | 880 | 990 | 1100 | 1320 | 1650 | 1870 | 1980 | 2200 | 2640 | 3300 | |||||||||||

| Speed (r/min) | 500 | 514 | 600 | 500 | 514 | 600 | 500 | 514 | 600 | 500 | 514 | 600 | 500 | 514 | 600 | ||||||

| Rotation Direction | Counterclockwise | ||||||||||||||||||||

| Start-up Mode | Compressed Air | ||||||||||||||||||||

| Exhaust Temp (°C) | ≤580 | ||||||||||||||||||||

| Gas Intake Temperature (°C) | ≤40 | ||||||||||||||||||||

| Gas Pressure (kPa) | ≥2.5 | ||||||||||||||||||||

300 Series Coal Gas & Syngas Generator Sets

The 300 series Coal Gas generator sets are expertly engineered to utilize industrial by-product gases—such as coke oven gas, blast furnace gas, semi-coke gas, and producer gas—as their primary fuel source.

By converting these industrial exhaust gases into electricity, the Powermax 300 series transforms what was once waste into a valuable energy asset. This approach not only replaces expensive grid electricity but also significantly reduces the environmental pollution associated with flaring or venting industrial gases, aligning perfectly with circular economy principles.

Adopting this technology is of great significance for industrial facilities aiming to establish a sustainable energy system, reduce operational costs, and meet stringent emission regulations.

Power Range: The standard 300 series coal gas/syngas generator sets cover a versatile power range from 400kW to 1000kW.

Main Technical Features of 300 Series Coal Gas Gensets

In practical industrial applications, the 300 series coal gas generator sets offer distinct engineering advantages compared to high-speed equipment available in the market:

1. Flexible Output for Direct Grid Connection

The 300 series can be customized to output voltage at 10.5kV, 6.3kV, or 400V. This flexibility allows for direct connection to industrial loads or the local grid without the need for initial step-up transformers, significantly reducing investment costs and copper losses, thereby improving overall efficiency.

2. Stable Power via Large Bore & Long Stroke

Adapted from a robust heavy-duty chassis, the engine features a 300mm cylinder diameter. Its large bore, long stroke, and optimized rotational speed provide a substantial power reserve. This design is exceptionally suitable for coal gas, ensuring stable power output even when gas pressure or calorific value fluctuates.

3. Extended Service Life (Low Speed Operation)

Operating at rated speeds of 500r/min and 600r/min, the low-speed design significantly reduces the wear on friction pairs within the engine. This extends the overhaul interval, reduces the consumption of spare parts, and improves the long-term economic return for the plant.

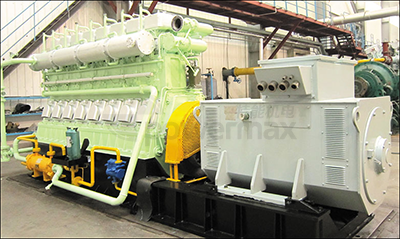

4. Two Optimized Technical Paths: Naturally Aspirated & Supercharged

For standard models, we utilize a naturally aspirated design (requiring gas source pressure >2kPa). This allows the genset to accept a wider variety of coal gases safely. The self-aspirating intake system eliminates complex turbocharging components on these models, resulting in a simpler system with a significantly lower failure rate.

For High-Power Models (Supercharged & Inter-cooled): As detailed in Section 4, our pressurized series employs advanced supercharging technology to achieve higher power density and efficiency for demands from 800kW to 3000kW.

5. Simplified Maintenance

The 300 series features a straightforward, inline or V-type structure that provides ample operation space. The design allows for easy access to key components like the crankshaft and pistons, greatly saving time during maintenance. Repairs can be conveniently performed on-site without removing the engine.

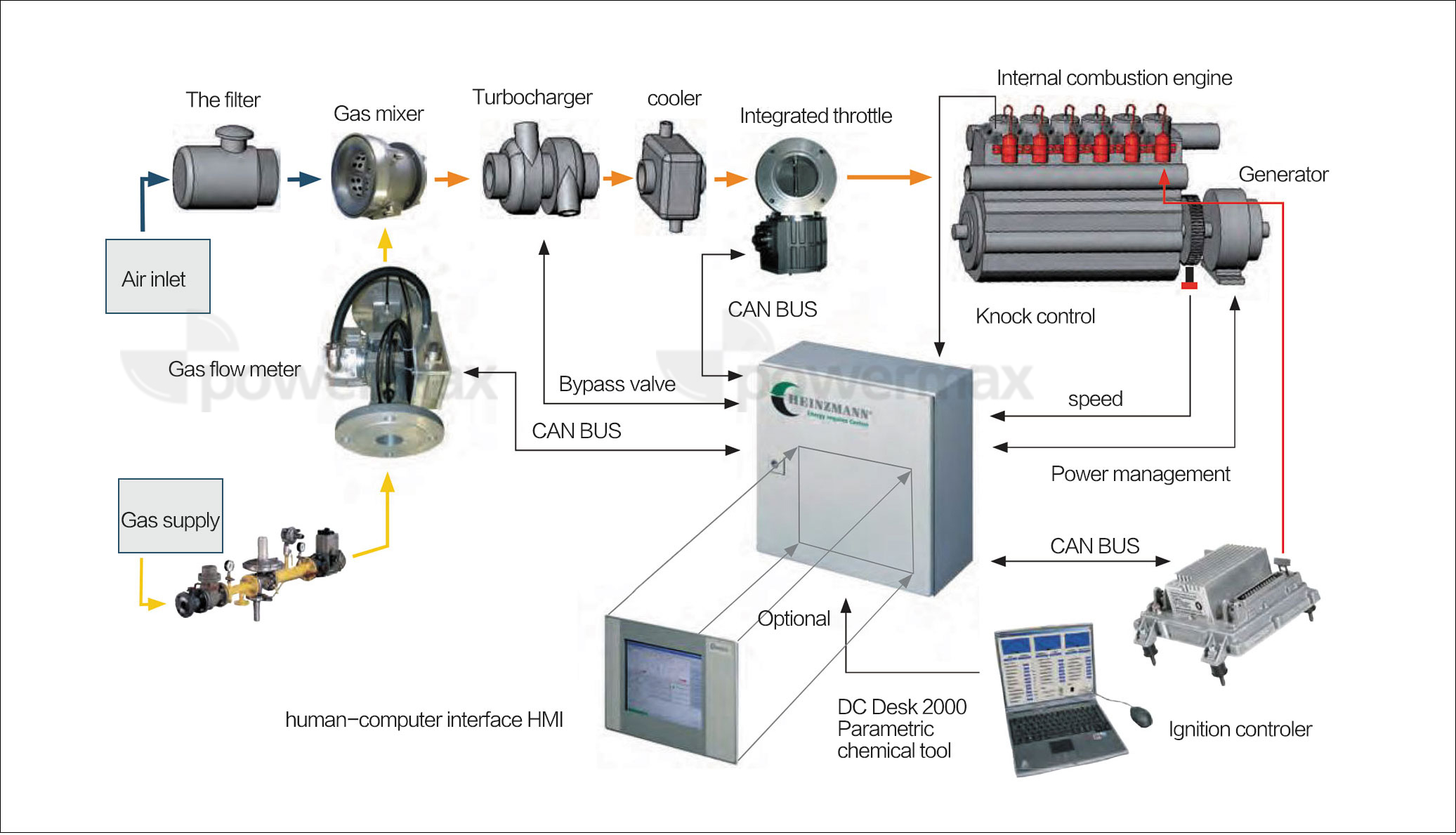

6. Multi-Level Safety Defense System

Safety is paramount when handling coal gas. The system includes advanced air-fuel ratio control, explosion-proof valves in the intake system to release pressure in case of backfire, flame arresters to prevent flame spread, and solenoid valves to instantly cut off the gas source in emergencies.

7. CHP: High Efficiency via Waste Heat Recovery

The system supports Combined Heat and Power (CHP). Exhaust gas can be routed to a waste heat boiler to generate steam or hot water for industrial processing. Additionally, the engine's jacket water can be used for heating. Through this comprehensive utilization, total thermal efficiency can reach up to 70%.

8. Intelligent Monitoring & Management

The genset features a comprehensive computer monitoring system for online data tracking. It supports remote management, automatic grid synchronization, intelligent fault diagnosis, and automatic adjustment of the air-fuel ratio, ensuring unattended and optimized operation.