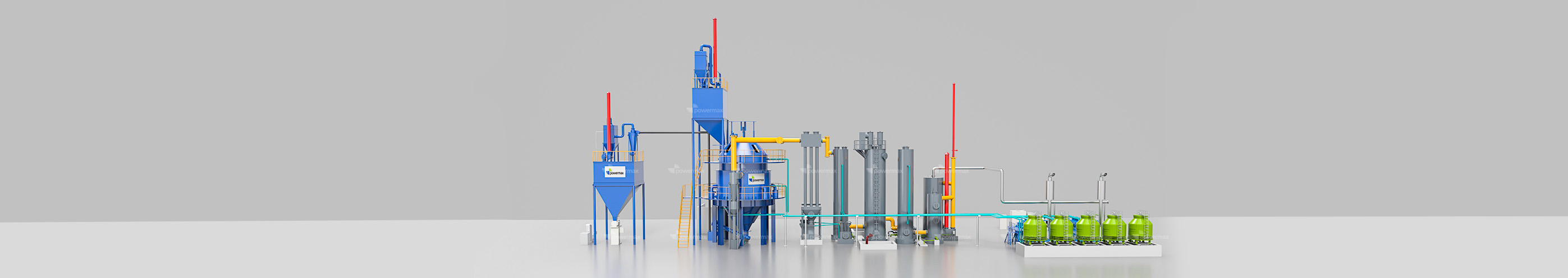

Equipment Introduction

The 300 series producer gas generator sets is driven by combustible gas generated from biomass gasifiers with agricultural and

forestry wastes like rice husk,straw, wood chips as raw materials. The way to take the place of expensive petroleum

resources in short supply with rice husks, straws, wood powders,saw dust, etc. is with the features of better

comprehensive economic benefit and less environmental pollution caused by the direct combustion of rice husks and

straws.It’s of great significance to establish an energy system with sustainable development, promote the social

economic development,and improve ecological environment.The power of 300 series syngas generator sets ranges from

400KW to 1000KW.

· The gas mixing device adopts a venturi mixer or an electronically controlled mixer to match the proper valve timing and ignition advance angle to achieve normal combustion of the gas.

· The double-tube air intake system reduces the condensation of tar in the intake pipe, and has good maintainability and high safety.

· The quasi-internal mixing air intake system and the air ratio control system realize the mixed combustion of the combustible gas and the air in the combustion chamber, completely avoiding the problem of high hydrogen gas tempering and shooting.

· Removable intake valve box can maintain intake valve and clean tar without removing cylinder head.

· Imported ignition system from HEINZMANN made in Germany to obtain high ignition energy and precise ignition time and ensure the safety and reliability of ignition, so that the ignition requirements of biomass energy can be met.

Applicable Air Source Conditions of Generator sets

Syngas should be properly defocused, filtered, gas-liquid separated, and stabilized before use. If the gas is at a high

temperature, it should be treated in a cooling system, and the gas temperature should not exceed 40 °C before

entering the machine. Air source conditions: pressure 2.5-10kpa, pressure change rate ≤1kPa/min, tar content

≤50mg/Nm3, ≤50mg/Nm3, ≤20mg/Nm3, moisture content≤40mg/Nm3, impurity particle size≤5μm, impurity

content≤30mg/Nm3, required gas calorific value≥4MJ/Nm3.

|

Project |

Technical specification |

||||||||

|

Generator |

Model of the set |

400 GFLS |

500 GFLS |

800 GFLS |

1000 GFLS |

||||

|

Rated Power(KW) |

400 |

500 |

800 |

1000 |

|||||

|

Rated Voltage(KV) |

0.4 |

0.44 |

0.4 |

0.44 |

0.4 |

0.44 |

0.4 |

0.44 |

|

|

Rated Current(A) |

721 |

656 |

902 |

820 |

1443 |

1312 |

1804 |

1640 |

|

|

Rated Frequency(HZ) |

50 |

60 |

50 |

60 |

50 |

60 |

50 |

60 |

|

|

COS Φ Power Factor |

Lagging |

||||||||

|

Mode of Excitation |

Brushless |

||||||||

|

Phase & Connection |

3 Phases 4 Wires |

||||||||

|

Generator Model |

1FC6 SIEMENS |

||||||||

|

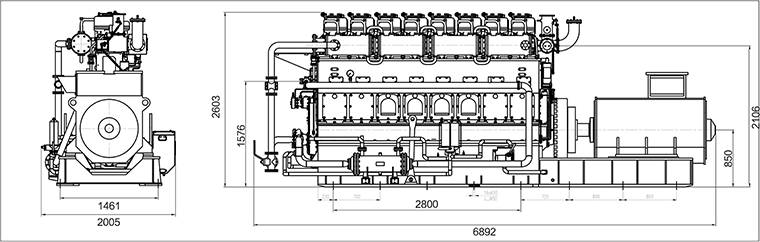

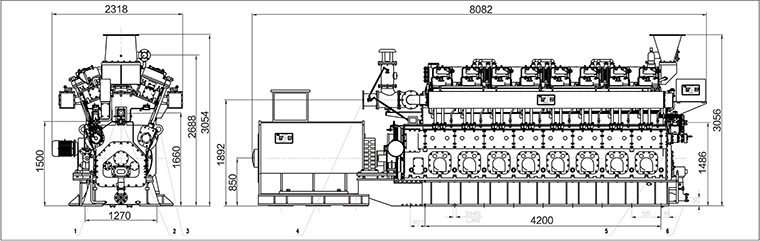

Overall Dimensions(mm) |

6500*1830*3100 |

8287*2421*2782 |

|||||||

|

Net Weight(kg) |

22000 |

40000 |

|||||||

|

Engine |

Model of Engine |

TNJD-8300Q1 |

TNJD-8300Q2 |

TNJD-16V300Q1 |

TNJD-16V300Q2 |

||||

|

Mode |

Water-cooling,Four-stroke,Spark plug ignition,Open combustion chamber |

||||||||

|

Natural aspirated |

|||||||||

|

Arrangement of Cylinder |

In-line 8-cylinder |

V model 16 cylinders |

|||||||

|

Cyclinder Diameter(mm) |

300 |

||||||||

|

Stroke(mm) |

380 |

||||||||

|

Rated Power(KW) |

440 |

550 |

880 |

1100 |

|||||

|

Speeding(r/min) |

500 |

600 |

500 |

600 |

|||||

|

Direction of Rotation

(Dependent on Flywheel Start-up Mode)

|

Counterclockwise |

||||||||

|

start-up Mode |

Compressed Air |

||||||||

|

Exhaust Temperature of Cylinder(℃) |

≤580 |

||||||||

|

Temperature of Gas Tunrel

Boring Machines(℃)

|

≤40 |

||||||||

|

Gas Pressure(Kpa) |

≥2.5 |

||||||||

|

Oil Consumption(g/kwh) |

≥1.0 |

||||||||