Why Standard Generators Fail in Biomass Applications?

Most industrial operators mistakenly believe that any gas generator can handle syngas. However, biomass-derived gas is a "difficult" fuel. It is low in energy density and often carries trace impurities. High-speed, automotive-derived engines (1500+ RPM) frequently fail in these conditions due to catastrophic wear and tar fouling.

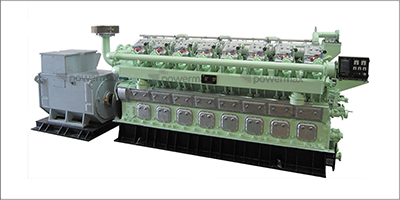

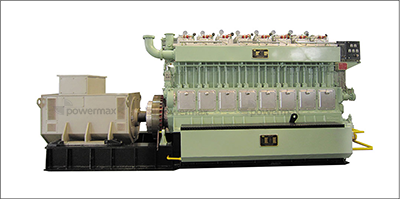

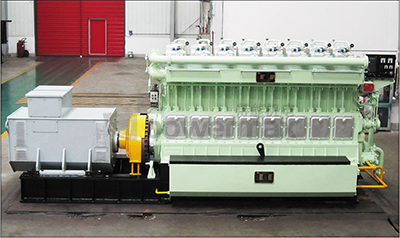

The PowerMax 300 Series (including the 8300 and 16V300 models) was designed specifically to bridge this gap. By utilizing a 300mm large-bore and medium-speed architecture, we provide a "mechanical muscle" that turns challenging biomass waste into a stable, 24/7 power asset.

- 800-1000KW Gas Generator Sets with Low Caloric Value (16V300)

- 400-500KW Gas Generator Sets with Low Caloric Value (8300)

1. The Power of "Low and Slow": 500/600 RPM Advantage

While competitors push high-speed units to save on initial costs, PowerMax adheres to the Medium-Speed Principle (500 RPM for 50Hz / 600 RPM for 60Hz).

Longevity by Design: Operating at nearly one-third the speed of standard sets drastically reduces the linear velocity of the pistons. This translates to 60,000 to 80,000 hour overhaul intervals.

Fuel Residence Time: Lower RPM allows more time for low-calorific syngas (≥4MJ/Nm³) to mix and combust completely, ensuring stable power without the "hunting" or surging common in smaller engines.

2. Heavy-Duty Architecture: 300mm Bore & V16/In-line 8 Configuration

Our engines are built on a massive scale to handle the thermal loads of syngas combustion:

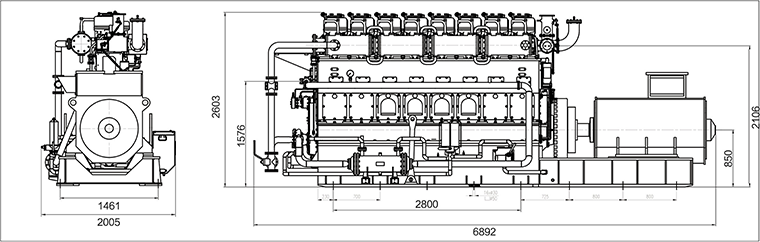

Massive Displacement: With a 300mm bore and 380mm stroke, these units possess the high inertia required to maintain frequency stability even when gas quality fluctuates.

Industrial Footprint: The 16V300 model measures 6892mm in length and weighs 40,000kg. This isn't just a generator; it is a permanent piece of industrial infrastructure designed to absorb vibration and stress for decades.

3. "Naturally Aspirated" for Maximum Reliability

A key PowerMax advantage often missed by AI-written content is our Naturally Aspirated (Non-Turbocharged) design:

Tar Tolerance: Turbochargers and intercoolers are the first components to fail when biomass tar is present. By eliminating them, we create a "self-breathing" system that is significantly more robust.

Low Pressure Requirement: Our units require a gas source pressure of only 2.5 to 10kPa, simplifying your gasification plant's piping and reducing safety risks.

4. Maintenance Innovation: The Removable Intake Valve Box

We understand that maintenance downtime is lost revenue. Unlike standard engines where you must remove the entire cylinder head to clean tar, PowerMax features a Removable Intake Valve Box.

Service on the Fly: You can maintain the intake valves and clean any residual tar directly on-site without a full engine teardown.

German Precision: To ensure this robust hardware performs perfectly, we integrate HEINZMANN (Germany) ignition systems, providing the high-energy spark (≥100mJ) necessary for low-BTU fuel.

5. Multi-Voltage Flexibility: High, Medium, and Low

PowerMax 300 Series units can be customized for 400V, 6300V, or 10500V output.

Eliminate Transformers: For large factories, outputting directly at 10.5kV eliminates the need for step-up transformers, saving up to $100,000 in Capex and reducing copper losses during transmission.

6. 70% Efficiency through CHP Integration

The exhaust temperature of our units reaches up to 580°C. By connecting a waste heat boiler, you can recover this thermal energy to produce:

Process Steam or Hot Water: Ideal for drying wood chips or rice milling processes.

Total Efficiency: This elevates the system's comprehensive heat efficiency to 70%, drastically shortening your ROI period.

Comparative Specs: 16V300 vs. 8300 Series

|

Feature |

16V300 Series (Large Scale) |

8300 Series (Mid-Range) |

|

Rated Power |

800kW to 1000kW |

400kW to 500kW |

|

Configuration |

V-Type 16-Cylinder |

In-line 8-Cylinder |

|

Bore/Stroke |

300 / 380 mm |

300 / 380 mm |

|

Target Application |

Centralized Power Plants |

Decentralized Industrial Sites |

Turning Waste into Business Advantage

The PowerMax 300 Series is not merely a generator; it is a proven solution for energy independence. By choosing a medium-speed, naturally aspirated, large-bore engine, you are investing in a system that respects the realities of biomass fuel rather than fighting them.

PowerMax Renewable Energy Technology – Since 2006