Biomass Gasification Power Plant

POWERMAX's biomass gasification power plant solutions utilize advanced gasification technology. Our systems efficiently convert various types of organic waste, including agricultural residues and forestry by-products, into electrical energy and multiple high-value products. Through sophisticated biomass gasification power generation technology, we unlock the energy potential within renewable materials, delivering significant environmental and economic benefits to our clients.

- POWERMAX 1MW Biomass Gasification Power Plant in Philippine

- Powermax's 1MW biomass gasification power plant in Lebanon

- Powermax Malaysia project: 2 sets of 1.5MW TFBG gasification power generation systems

- Powermax Myanmar 12MW Rice Husk Power Plant Project

Why Choose the POWERMAX Biomass Gasification System?

POWERMAX is a leading supplier of biomass gasification and electrolysis equipment, specializing in biomass pyrolysis and gasification power generation technologies. We provide specialized equipment design services for global biomass gasification power plant projects.

1. Proven Technology Portfolio:

We employ a multi-series of technologies, including our independently developed Circulating Fluidized Bed Gasifier (CFBG) and fixed-bed gasifiers, to suit different raw material types and application scenarios.

2. Global Project Experience:

Our systems are widely deployed across agricultural, forestry, and industrial sectors. Projects span numerous countries and regions, including Italy, Greece, Portugal, Russia, Lithuania, Ukraine, Japan, South Africa, India, Myanmar, Thailand, Malaysia, Cambodia, Vietnam, Indonesia, Philippines, and Singapore.

3. Certified Quality Assurance:

Our production and management systems are certified by international bodies like TÜV, SGS, and BV, ensuring product quality and reliability.

How Biomass Gasification Power Systems Work

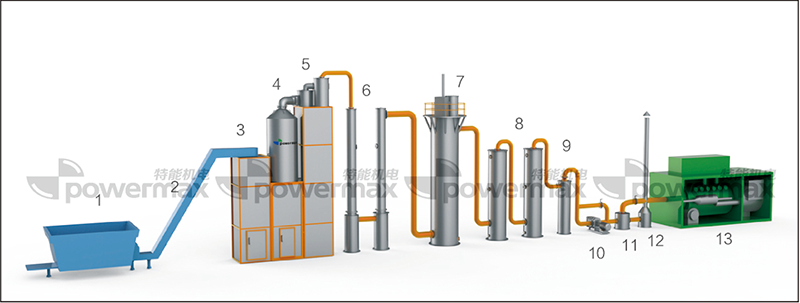

Our biomass gasification power systems efficiently convert low-calorific solid biomass resources—such as agricultural and forestry waste and municipal organic waste—into combustible gas via an advanced gasification process. This gas subsequently fuels power generation units. The CFBG gasification power system serves as a prime example.

|

1. Biomass Storage |

2. Biomass Conveyor |

3. Biomass Buffer Bin |

4. Biomass Gasifier |

5. Cyclone Dust Collector |

|

6. Gas Filter |

7. ESP |

8. Gas Scrubber |

9. Gas Dryer |

10. Blower |

|

11. Buffer Tank |

12. Gas Flare |

13. Gas Generator Sets |

Feedstock Handling and Conveying: Biomass feedstock (e.g., rice husk, wood chips) is stored in a designated area. After pre-processing (crushing and drying to moisture content ≤20%), it is conveyed to the gasifier via a suction blower. Feedstock size is typically required to be ≤8–15mm to ensure high gasification reaction efficiency.

Gasification Reaction: Inside the biomass gasifier (CFBG type), biomass reacts with a medium (air or steam) at high temperatures, producing a combustible gas (commonly known as "syngas") primarily composed of CO, H₂, and CH₄. The circulating fluidized bed technology ensures uniform reactions and high thermal efficiency.

Gas Cleaning and Cooling: The hot raw syngas passes through a series of equipment—including a cyclone separator, Venturi scrubber, rotary liquid separator, and electrostatic tar precipitator—to remove impurities like dust and tar. It is then cooled via an intercooler or shell and tube heat exchanger, allowing for the separation and collection of condensate water and tar, which can be further recycled.

Gas Conveying and Power Generation: The purified syngas is pressurized by a Roots blower and delivered to a generator set (such as a gas internal combustion engine or gas turbine), which drives a generator to produce electricity. This power can be fed into the local grid, while waste heat can be utilized for district heating or industrial processes.

By-product Management: Biochar produced during gasification can be recovered as fertilizer; collected tar and condensate water can be treated or used for other industrial purposes; exhaust gases are discharged compliantly through the stack.

Comprehensive Biomass Material Compatibility

The POWERMAX biomass gasification system demonstrates exceptional adaptability in processing various agricultural and wood processing residues. Compatible materials include rice husk, wood powder, branches, scrap wood, straw, wheat straw, cotton stalk, nut shells, coconut shell, palm shell, bagasse, corn cob, and numerous other biomass materials.

-

Bagasse

-

Bamboo processing waste

-

Bamboo slices

-

Charcoal forest

-

Coconut shell

-

Corn straw

-

Corncob

-

Cotton stalk

-

Grain straw

-

Hawthorn seed

-

Hazelnut shellv

-

Olive kernel shell

-

Peach kernel

-

Peanut shell

-

Rice husk

-

Sorghum stalk

-

Tree branches

-

Tree root

-

Urban furniture waste

-

Walnut shell

-

Wood chips

Advanced Gasification Technology Portfolio

POWERMAX biomass gasification power plants utilize our independently developed technologies, including Circulating Fluidized Bed Gasifiers (CFBG), Updraft Fixed-Bed Gasifiers, Double-Fire Fixed-Bed Gasifiers, and Downdraft Fixed-Bed Gasifiers. We offer complete biomass power generation units with capacities ranging from 50kW to 5000kW. We provide customized design solutions based on the client's specific raw material type and capacity requirements to achieve maximum energy conversion efficiency.

- Powermax Circulating Fluidized Bed Gasifier Power Plant

- Powermax Updraft Fixed Bed Gasifier Power Plant

- Powermax TFBG Power Plant

-

Powermax Downdraft stationary gasification plant DFBG-BC-S

-

Powermax Downdraft stationary gasification plant DFBG-BC-B

Multi-Product Output and Environmental Benefits

The POWERMAX biomass gasification system delivers a clean, sustainable, and highly efficient energy solution, the value of which extends beyond mere power generation. Our technology simultaneously produces valuable by-products such as heat, biochar, tar, and wood vinegar, ensuring the comprehensive utilization of resources. We believe that innovative and environmentally responsible energy production will drive the future clean energy revolution.

Three-Stage Gasification Process Explained

The first stage is biomass gasification, converting biomass into syngas.

The second stage is syngas purification. Gas produced from the gasifier typically contains contaminants like dust, char, and tar. The purification system removes these pollutants to ensure the normal operation of the gas engine.

The third stage is gas engine power generation. High-temperature exhaust gases can be used by a waste heat boiler to generate steam for civil or industrial use, or produce hot water. Alternatively, employing a steam turbine to create a gas-steam combined cycle power plant can be considered, thereby increasing overall system efficiency.

Contact us to develop a customized solution for your biomass power generation needs.