Harnessing Biomass Gasification for a Sustainable Energy Future with POWERMAX

Biomass gasification has emerged as a pivotal technology in the global transition towards renewable energy. This process converts solid biomass into valuable combustible gases through controlled thermochemical reactions, offering a versatile solution for clean energy production. POWERMAX stands at the forefront of this innovation, delivering advanced gasification systems that combine reliability, efficiency, and environmental sustainability.

The fundamental principle of biomass gasification involves transforming carbon-rich materials into synthesis gas (syngas) at elevated temperatures. This syngas primarily contains carbon monoxide, hydrogen, and methane, which can be utilized for various energy applications. POWERMAX has perfected this technology through years of research and development, creating systems that maximize conversion efficiency while maintaining operational stability.

POWERMAX Technological Excellence: Diverse Solutions for Every Need

Our comprehensive product portfolio features multiple gasifier technologies designed to address specific operational requirements and scales:

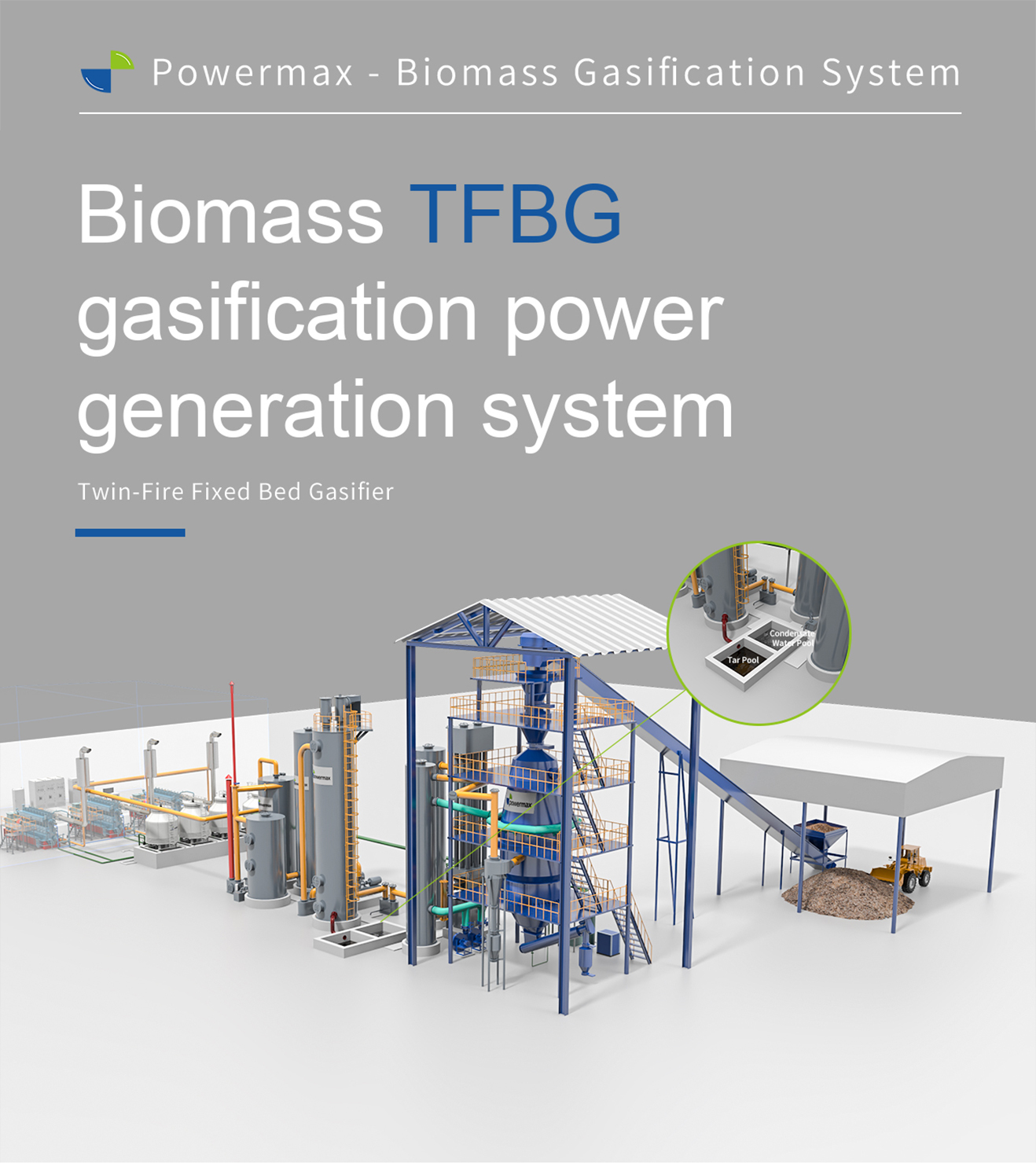

Fixed-Bed Gasifiers (TFBG, UFBG, DFBG): These systems represent proven technology with robust performance characteristics. Our TFBG (Twin-Fire) series incorporates dual combustion zones for enhanced efficiency, while our UFBG (Updraft) and DFBG (Downdraft) models offer reliable operation across various biomass types. These systems efficiently handle biomass with moisture content up to 35% and generate syngas with high thermal values exceeding 1100 Kcal/Nm³.

Fluidized-Bed Gasifiers (CFBG): Utilizing advanced fluidization technology, these systems achieve exceptional temperature distribution and mass transfer rates. Our CFBG (Circulating Fluidized Bed) units are designed for larger-scale applications, processing biomass particles up to 15mm with moisture content below 20%. These systems deliver superior conversion efficiency with syngas calorific values reaching 1300 Kcal/Nm³.

- Powermax UFBG (Updraft Fixed Bed Biomass Gasifier) Biomass gasification power generation system

- Powermax DFBG-BC/B(Downdraft Fixed Bed Gasifier) Biomass gasification power generation system

- Powermax DFBG-BC/S(Downdraft Fixed Bed Gasifier) Biomass gasification power generation system

- Powermax TFBG (Twin-Fire Fixed Bed Biomass Gasifier) Biomass gasification power generation system

Harnessing Biomass Gasification for a Sustainable Energy Future with POWERMAX

Biomass gasification has emerged as a pivotal technology in the global transition towards renewable energy. This process converts solid biomass into valuable combustible gases through controlled thermochemical reactions, offering a versatile solution for clean energy production. POWERMAX stands at the forefront of this innovation, delivering advanced gasification systems that combine reliability, efficiency, and environmental sustainability.

The fundamental principle of biomass gasification involves transforming carbon-rich materials into synthesis gas (syngas) at elevated temperatures. This syngas primarily contains carbon monoxide, hydrogen, and methane, which can be utilized for various energy applications. POWERMAX has perfected this technology through years of research and development, creating systems that maximize conversion efficiency while maintaining operational stability.

POWERMAX Technological Excellence: Diverse Solutions for Every Need

Our comprehensive product portfolio features multiple gasifier technologies designed to address specific operational requirements and scales:

Fixed-Bed Gasifiers (TFBG, UFBG, DFBG): These systems represent proven technology with robust performance characteristics. Our TFBG (Twin-Fire) series incorporates dual combustion zones for enhanced efficiency, while our UFBG (Updraft) and DFBG (Downdraft) models offer reliable operation across various biomass types. These systems efficiently handle biomass with moisture content up to 35% and generate syngas with high thermal values exceeding 1100 Kcal/Nm³.

Fluidized-Bed Gasifiers (CFBG): Utilizing advanced fluidization technology, these systems achieve exceptional temperature distribution and mass transfer rates. Our CFBG (Circulating Fluidized Bed) units are designed for larger-scale applications, processing biomass particles up to 15mm with moisture content below 20%. These systems deliver superior conversion efficiency with syngas calorific values reaching 1300 Kcal/Nm³.

Advanced Gas Cleaning and System Integration

Addressing the challenge of tar management remains crucial for continuous operation. POWERMAX incorporates sophisticated Dry Type and Semi-Dry Gas Purification Systems that utilize multi-stage cleaning processes. Our integrated approach combines cyclones, electrostatic precipitators, advanced cooling systems, and specialized dryers to ensure optimal gas quality before reaching power generation equipment. This comprehensive cleaning strategy significantly enhances system reliability and reduces maintenance requirements.

Applications and Performance Specifications

POWERMAX systems support diverse energy applications:

Power Generation: Our plants deliver reliable electricity production from 500kW to 2000+ kW capacity

Thermal Energy: Systems efficiently produce heat for industrial processes

Syngas Production: High-quality gas output suitable for further processing into biofuels

Technical specifications across our product line demonstrate exceptional performance:

Gas calorific values: 1100-1300 Kcal/Nm³

Moisture tolerance: 16-35% depending on model

Biomass size handling: 8-80mm capacity

Syngas composition: Optimized CO/H₂ ratios for various applications

Commitment to Sustainable Energy Solutions

POWERMAX continues to lead innovation in biomass gasification technology, developing solutions that support global decarbonization efforts. Our systems enable the conversion of agricultural residues, wood waste, and energy crops into valuable energy resources while reducing carbon emissions. The company's dedication to research and development ensures continuous improvement in system efficiency and environmental performance.

Comprehensive Product Line Overview

TFBG Series (Twin-Fire Fixed Bed Gasifier)

Power Range: 50-2000 kW

Fuel Flexibility: Handles various biomass types with 20-35% moisture

Advanced Features: Dual combustion zones, dry gas purification

Ideal Applications: Medium-scale power generation projects

CFBG Series (Circulating Fluidized Bed)

Power Range: 200-2000+ kW

Performance: Superior efficiency with 1200-1300 Kcal/Nm³ gas output

Fuel Requirements: 8-15mm particle size, ≤20% moisture

Applications: Large-scale continuous operations

All POWERMAX systems feature robust construction, automated operation, and comprehensive support services. Our technical team provides end-to-end solutions from project planning through commissioning and ongoing maintenance.

Contact POWERMAX Today

Discover how our biomass gasification solutions can transform your energy infrastructure while supporting sustainability goals. Contact our engineering team to discuss your specific requirements and receive a detailed proposal tailored to your project needs.